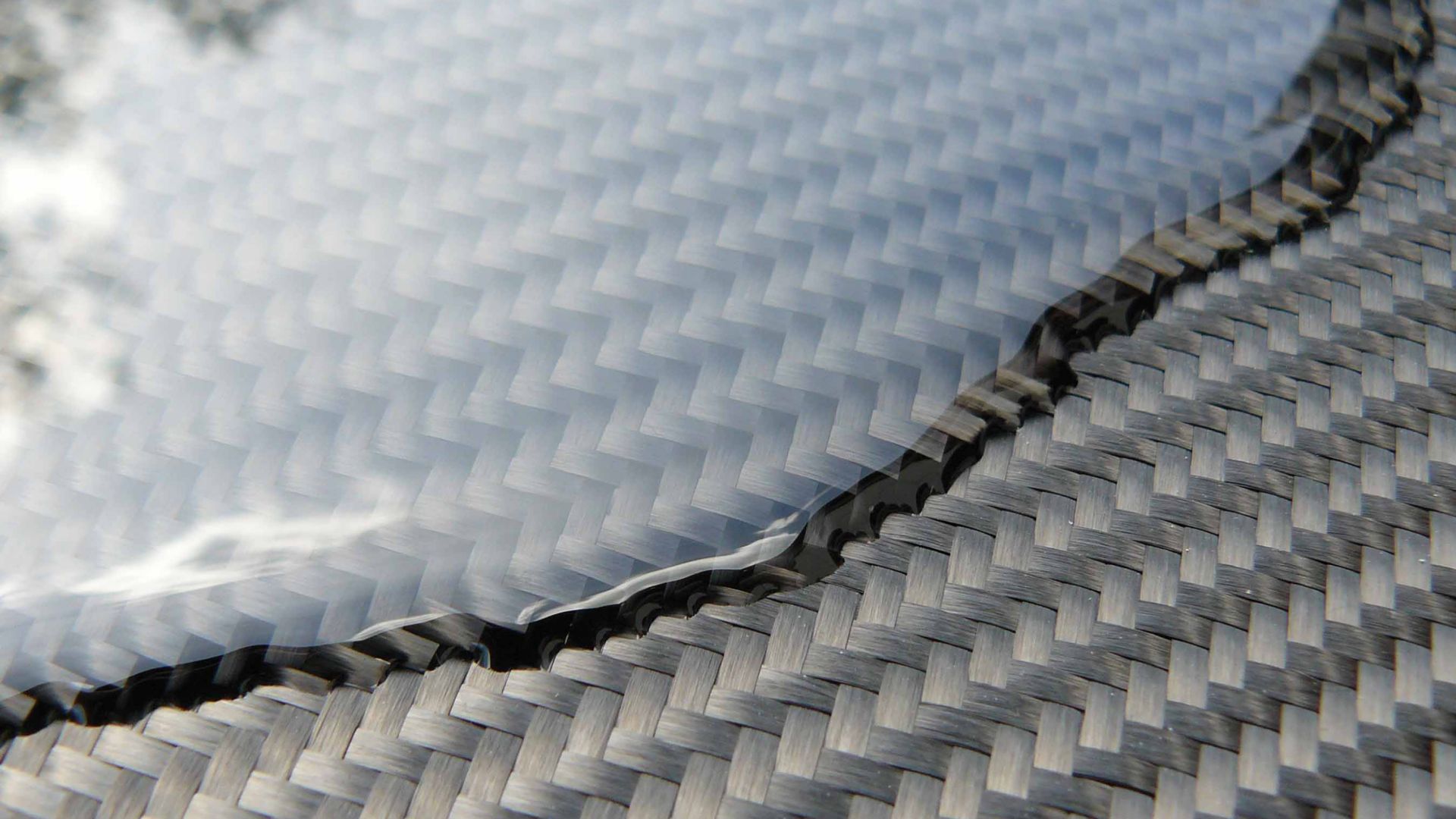

High Performance Composite Resin Systems

A wide range of high performance composite systems aimed for parts production as well as for mold making applications. These high performance composite resins are designed to meet the highest standards of production, process efficiency and end-use performance.

Our composite matrix systems, based on epoxy or polyurethane, are specially formulated to give the optimal viscosity as well as other processing parameters to meet the different specific processes in the composite industry like wet lay-up, vacuuminfusion, RTM, filament winding and pultrusion.

The systems are specially designed for different working temperatures ranging from 80 °C up to 225 °C. Additionally it is possible to adjust the reactivity of the systems by using different hardeners.