Tunnel boring machines (TBMs) are at the cutting edge of underground construction, revolutionizing how we excavate through rock and soft ground without the need for traditional excavation methods. As heavily urbanized cities expand and infrastructure demands grow, mechanized tunneling is shaping the future of underground development. Sika delivers a powerful suite of specialized products engineered to enhance TBM performance at every stage, ensuring faster, safer, and more efficient tunnel excavation and construction.

Transforming Underground Construction with TBMs

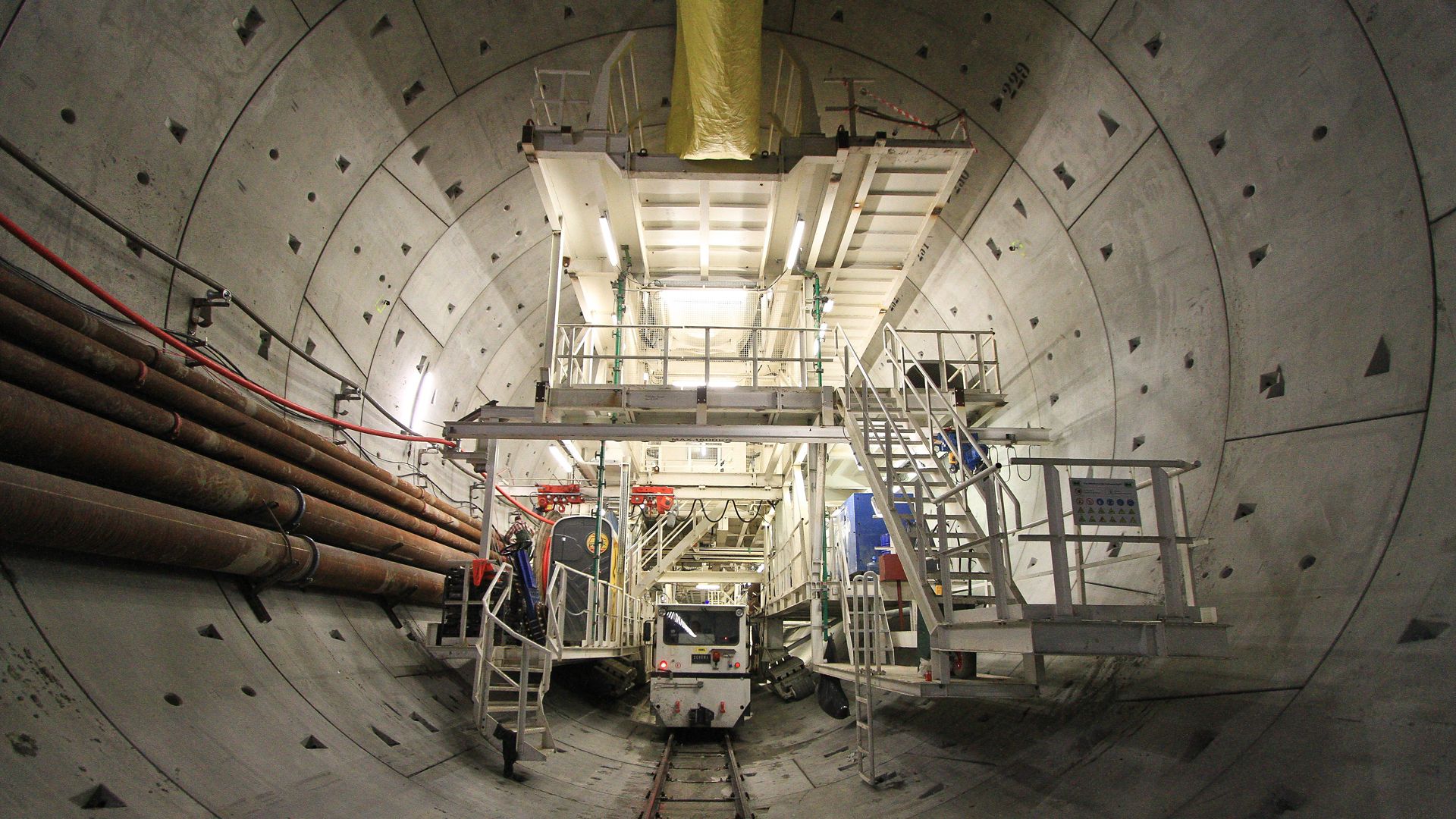

TBMs are revolutionizing excavation, minimizing ground disturbance and making them the ideal choice for tunneling in dense urban environments and not only. Their precision engineering creates smooth tunnels, significantly reducing the cost of final lining. Compared to conventional excavation methods, TBMs dramatically shorten the total construction time of long tunnels, accelerating infrastructure development.

Over the past decade, advancements in TBM technology have introduced a diverse range of solutions to tackle complex geological challenges. These innovations include new Earth Pressure Balance (EPB) TBMs and more sophisticated Slurry TBMs for soft ground; Variable Density (VD) TBMs and Dual Mode TBMs for mixed ground conditions; Single Shield and Double Shield TBMs for stable, non-groundwater-bearing hard rock formations.

The evolution of continuous mining techniques and the integration of artificial intelligence (AI) are further transforming the mechanized excavation. AI-driven TBMs optimize excavation speed, adapt to real-time ground conditions, and enhance operational safety, while continuous mining systems reduce downtime and maximize efficiency. These cutting-edge advancements are setting new benchmarks for speed, precision, and sustainability in underground construction.

Additionally, microtunnelling machines (MTBMs) have become indispensable for underground utility projects, enabling rapid excavation with minimal surface disruption.

As cities expand and the demand for efficient underground solutions grows, TBMs continue to redefine the possibilities of modern tunneling.

What Drives Success in TBM Operations

TBMs are at the forefront of modern underground construction, delivering efficiency, precision, and reduced surface disruption. Success hinges on selecting the right TBM for specific geological conditions, maintaining rigorous machine upkeep, ensuring flawless alignment, and deploying advanced ground support systems. Beyond technical performance, safety, meticulous project planning, and cost control are essential to completing tunnels on time and within budget.

What Matters Most to our Customers

Efficiency, reliability, and cost control define customer priorities in TBM operations. Speedy excavation, minimal downtime, and robust machine performance are critical to meeting tight project deadlines. Safety, environmental impact, and ground settlement control are non-negotiable concerns. Additionally, customers value comprehensive post-sales technical field support, ready availability of expert technical assistance to ensure seamless tunneling operations.

Efficiency & cost

Speedy excavation

Minimal downtime

Safety & environment

Ground settlement

Technical support

The Biggest Challenges in TBM Operations

Tunneling is unpredictable - TBM projects must navigate shifting ground conditions, high maintenance demands, and machine wear. Precision is key: even minor misalignments can derail progress. Managing water ingress, controlling ground settlement, and handling complex logistics add further layers of difficulty. Tight schedules, environmental regulations, and the need for expert personnel make overcoming these challenges a test of skill and innovation.

Common excavation issues and how to overcome them

Even with state-of-the-art TBMs, excavation presents challenges such as ground instability, water infiltration, cutter head blockages, and high machine wear. Unexpected geological conditions and material clogging can disrupt progress. Tackling these issues requires proactive monitoring, adaptive engineering solutions, and cutting-edge TBM solutions to keep projects on track.

1. Soil Conditioners for EPB TBM Excavation

Injecting foams, polymers and other additives into the tunnel face plays a crucial role in transforming the properties of the excavated ground. Soil conditioning improves mechanical and physical properties of soils, including plasticity, texture, and permeability, helping to optimize excavation conditions and accelerate the progress of the TBM.

The effectiveness of soil conditioning depends on selecting the right type and quantity of solutions, choices that are guided by the specific geological conditions and the TBM equipment in use.

Sika Solutions for Soil Conditioning

Not all ground conditions are ideal for mechanized excavation. In challenging environments - such as heterogeneous soils containing gravel, sand, and water - soil conditioning foaming agents can significantly improve the performance and advance rates of EPB TBMs.

The Sika® Stabilizer TBM range offers high-performance liquid foaming agents specifically designed for application in EPB machines. These formulations help to modify the properties of excavated soil, making tunneling more efficient and controlled.

Our portfolio includes:

Sika® Stabilizer-1118/1113

Standard foaming agents for granular soils

Sika® Stabilizer-1215/1219

New generation of foaming agents for granular soils

Sika® Stabilizer-1514/1518

Foaming agents with anti-clay polymers for clays

Sika® Stabilizer-1111

Foaming agents for granular abrasive soils

In response to global growing environmental expectations, Sika has developed a fully comprehensive line of foaming agents within the Sika® Stabilizer TBM family. These eco-conscious products are readily biodegradable, aiming to reduce the environmental impact of conditioned and excavated soils after disposal. Depending on the tunnel geology and site-specific conditions, these foaming agents can contribute to more sustainable tunneling operations.

Polymers play a vital role in improving efficiency and control during TBM operations. Sika offers a specialized range of solutions designed to optimize ground behavior in challenging excavation conditions.

Key benefits of Sika polymer applications:

- Stickiness reduction and adhesion prevention

- Clogging prevention and improved handling of excavated soil

- Minimized soil attachment to metal surfaces within the TBM

- Improved torque and TBM penetration rate

- Soil homogeneity improvement

- Reduced segregation in the mixing chamber for consistent soil conditioning

- Improved pressure build-up and ground settlements

- Ground drying assistance

- Effective moisture reduction and control in wet or waterlogged soils

Our portfolio includes:

Sika® Stabilizer-3710/3750/3001

Super water absorber polymers for water control

Sika® Stabilizer-3212/3214/3215

Pure polymers for clay

Sika® Stabilizer-3710/3750/3001 TBM

Sika® Stabilizer-3710

Engineered for TBM Tunneling

Sika® Stabilizer TBM polymers - such as super water-absorbing agents, viscosity modifiers, foam stabilizers - are specifically formulated to meet the demands of modern tunneling projects. These advanced solutions help ensure optimal TBM performance across a wide range of soil types and geological conditions.

Sika solutions for hard rock TBMs are engineered to reduce wear on cutting tools, control dust, and enhance soil transportation outside the tunnel.

Our portfolio includes:

Sika® Stabilizer-1513/1516

Foaming agents for wear and dust reduction

These benefits lead to lower maintenance and cutting tool replacement costs, reducing TBM downtimes, and a more efficient TBM excavation cycle. By improving operational continuity and safety, they support faster tunnel construction and greater overall project efficiency, making them ideal not only for hard rock TBMs but also for EPB TBMs excavating in rock.

2. Backfill Grouts

Sika is actively involved around the world in many TBM projects, providing a wide range of solutions for TBM backfilling according to each project's specific requirements and challenges.

Sika Solutions for Backfilling Grouts

In shielded TBM excavation, the precast concrete segments are installed with the advance of the machine to build the tunnel, and an annular gap is spontaneously created by the passage of the TBM between these segments and the ground.

The simultaneous filling of this annular gap with the advance of the TBM, is essential to:

- Minimize any potential ground settlement

- Avoid floating of the last installed 3-4 rings

- Allow a mild transfer of longitudinal and transversal loads from the ground to the segments

- Prevent the ingress of water into the tunnel

Sika is capable of working with different types of backfill grout applications:

- Mono-component grouts (1k)

- Two-component grouts (2k)

- Pea gravels for hard rock TBMs

The use of two components grouts have become extensively widespread in the last 15 years, particularly in EPB applications; Component A is a mixture of cement, bentonite, water and a retarder (sometimes enriched with aggregates like limestone, sand or alternative binders such as fly ash, GGBFS, slag, micro silica) which is accelerated by Component B sodium silicate (as activator). Components A and B meet immediately prior to the injection point through the TBM tail shield, to form the final Component A+B. Upon mixing, the grout transitions from a superfluid liquid to a gel within seconds. The final set material achieves strength comparable to the surrounding ground, effectively filling all gaps and voids before hardening.

Our portfolio includes:

Sika® Stabilizer-5010/5015

SikaTard®

Retarders/ stabilizers

Sika® Stabilizer-6010/6015/6018/6001

Sigunit®

Accelerators for 2k grouts

Plastiment®

Plasticizers

Global Warming Potential (GWP) is the measure of the climate impact of the greenhouse gases emitted during the life cycle of the backfill grout. It indicates how much heat these emissions will trap in the atmosphere over time, relative to carbon dioxide.

Sika offers sustainable, high-performance backfill grout solutions designed to lower the environmental impact of your construction projects. Formulated with low-carbon materials, our mix designs significantly reduce CO₂ emissions while maintaining excellent durability and stability. Ideal for TBM tunneling, our grouts support green building goals without sacrificing quality. Best of all, no changes are required in your existing batching process or injection methods, ensuring a seamless transition to an eco-friendlier application. With our reduced CO₂ backfill grouts, you can meet sustainability targets and reduce your project’s carbon footprint without additional effort or investment in new equipment.

Learn More

3. Tail Sealant Greases

Tail seal greases are injected between the rows of brushes in the gap between the tail shield and the lining segments to prevent water, soil, and the backfilling grout from entering the TBM.

Sika greases are specifically formulated for use in TBM with or without groundwater. Our greases are designed to ensure optimal performance while maintaining chemical compatibility with environmentally sensitive zones. Their use supports compliance with urban tunneling safety standards and environmental protection guidelines, reducing the risk of groundwater contamination during TBM operations.

Sika Solutions for Tail Sealant Greases

All Sika tail sealant greases are designed to comply with all standard test methods currently known in the TBM industry, among which, for example, they all pass the Matsumura Water Pressure Test at 34 bars.

Our greases are well pumpable and adaptable to all plunger pump systems in modern TBMs. In addition, they are all technically and chemically compatible with all other similar greases in the market.

Our portfolio includes:

Sika® Stabilizer-2132 TBM

Old generation first-fill

Sika® Stabilizer-2232 TBM

Old generation pumping grade

Sika® Stabilizer-2131 TBM

New generation, fire resistant first-fill

Sika® Stabilizer-2231 TBM

New generation, fire resistant pumping grade

4. Main Bearing Greases & Lubricants

The main bearing is the key component of the TBM, not only because it allows the cutter head to spin against the ground but because of its cost. Therefore, its protection and maintenance are the utmost duty of a contractor.

Experience shows that most failures of TBM main bearings are related to a loss of lubricants, or to the entry of contaminants from the excavation chamber. For this reason, it is absolutely essential to have the system working with reliable products.

Sika Solutions for Main Bearing

Excluder grease forms a barrier to prevent the ingress of water or soil into the main bearing and ensure reliable machine performance.

Our portfolio includes:

Sika® Stabilizer-2031 TBM is a grease based on synthetic oil used to protect the main bearing of TBM. The Product resists high water and ground pressures, it has very good lubricating and pumping properties, and adheres very well to all surfaces.

Sika® Stabilizer-2032 TBM is a high quality multipurpose lubricant suitable for a wide range of TBM main bearings. It is designed for main bearing lubrication, as a screw conveyor drive assembly grease and as a rotary swivel grease.

5. Slurry TBMs

Slurry TBMs are advanced excavation systems designed for soft and mixed ground conditions, especially where high water content or unstable soils are encountered. By using pressurized slurry to balance earth and water pressures at the tunnel face, they ensure enhanced controlled excavation and maintain ground stability. Ideal for urban environments, slurry TBMs minimize surface settlement and environmental impact while enabling precise tunneling through complex geologies.

In recent years, the use of slurry TBMs has seen a significant rise, driven by the increasing demand for infrastructure in dense urban areas and their proven performance in challenging ground conditions worldwide.

Sika Solutions for Slurry TBMs

Sika provides a diverse range of sodium bentonites, spanning low to high plasticity, suitable as binders and viscosity im¬provers with varying swelling properties. All Sika bentonites are guaranteed through an ISO 9001:2000 certified quality management system.

Our portfolio includes:

Sika® Stabilizer-4001/4002/4003/4004

Basic to polymerized types of bentonites

VMAs play a crucial role in enhancing the performance of bentonite-based slurries. These admixtures adjust the rheological properties of the slurry, increasing its viscosity and yield stress to maintain consistent pressure at the tunnel face. By improving the stability and flow characteristics of the bentonite suspension, viscosity modifiers help to build the mud cake, prevent filter losses, reduce sedimentation, and ensure a homogeneous slurry mixture. This improved stability allows the slurry to effectively support the excavation face, balance earth and water pressures, and minimize the risk of collapse or settlement, especially in highly permeable or mixed ground conditions.

Our portfolio includes:

Sika® Stabilizer-4601/4602

Bentonite extenders for tunnel face stabilization

Sika® Stabilizer-4501

Bentonite thinner for clay dispersion

Sika® Stabilizer-4141

Flocculant for solid/ liquid separation

With a membrane

The filter cake membrane forms a thin impermeable layer directly on the wall, transforming excess slurry pressure into effective support stress in low permeability grounds.

The slurry creates only a surface impermeabilization, typically several millimeters thick.

Or with a penetration zone

In penetration zone formation, excess slurry pressure transfers to the soil skeleton

along the entire penetration depth through shear stresses between suspension and soil grains in moderately to highly permeable grounds.

The slurry penetrates ground pores before stopping and setting, constituting the impermeable interface.

This zone varies from several tens of centimeters to a few meters in thickness.

6. Admixtures for Precast Segments

During the production of concrete segments for tunnels, it is important that the concrete can be placed without the formation of hollows or voids. The mix must also have a high early strength to reduce the curing time and de-mold the segments as fast as possible. With a high range water reducer, a low water/cement ratio can be achieved that will result in increased early strengths and increased durability.

Sika Solutions for Precast Concrete Segments

After just a few hours, concrete reaches sufficient strength for proceeding with the production cycle. To meet these requirements, special admixtures have been developed using Sika® ViscoCrete® technology.

Sika® Separol® release agents are used to ensure easy de-molding and improved concrete surfaces.

In some conditions, the segments forming the permanent lining can be exposed to aggressive influences in the ground. In such cases, Sikagard® products are used to provide a high level of protection.

Additional Sika admixtures such as Sikament®, SikaTard® and SikaPlast® are also used to meet specific demands.

Enhance concrete mixes to the next level of low carbon footprint. Connect with your local Sika Team for expert guidance on eco-friendly concrete mix designs tailored for precast segments and concrete lining.

Our solutions not only reduce carbon footprint, but also elevate performance and durability. Let us enable the way for a more sustainable construction future.

7. Injections

Injections in TBM tunneling are critical for ensuring ground stability, structural integrity, and water control, before, during and also after TBM excavation.

Various injection systems deliver specialized materials - such as resins, acrylates, cementitious materials - into the ground or tunnel lining to fill voids, reduce permeability, and support excavation, adapting to changing geological conditions in real time.

Sika Solutions for Injections

Our portfolio includes:

SikaInject®-501 DE

Two-component silicate foam-resin with a high foaming factor (up to 30 times)

SikaInject®-668

Two-component compact silicate resin with a short reaction time (around 40 seconds)

Our portfolio includes:

SikaInject®-210 DE

Very fast two-component structural polyurethane foam

Our portfolio includes:

SikaInject®-304 DE

Acrylate-based, three-component injection resin

8. Waterproofing

Waterproofing systems for TBM shafts, stations, and cross passages must meet the highest standards of durability and resistance to exposure and stress. These projects require precise construction methods, efficient installation sequences, and cost-effective solutions. At the same time, sustainability is becoming increasingly important, driving the need for systems that conserve energy and water while helping to reduce CO₂ emissions.

Sika Solutions for Waterproofing Underground Structures

Explore how Sika’s waterproofing solutions for underground structures combine flexible membranes, liquid membranes, admixtures, joint systems and injection grouts to deliver durable, high-performance protection under extreme conditions.

Mastering TBM Operations with Sika

Sika is your trusted partner for tunneling professionals worldwide, delivering high-performance materials, expert guidance, and innovative solutions that redefine TBM efficiency. Our portfolio includes advanced chemical solutions designed to cope with every kind of geology, every type of tunnel boring machine, to enhance durability and optimize performance.

With global expertise, customized solutions, and a commitment to sustainability, Sika ensures TBM operations run faster, safer, and more cost-effectively, helping our customers push the boundaries of underground construction.